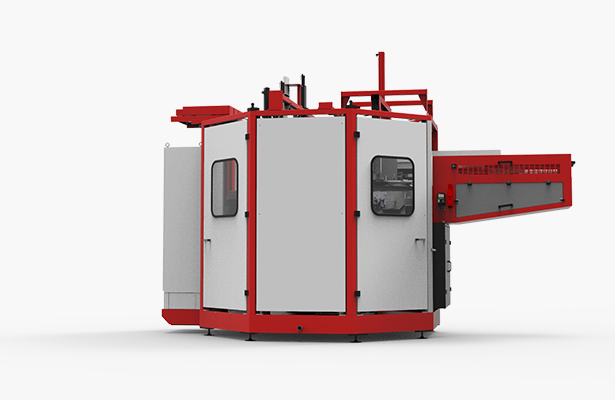

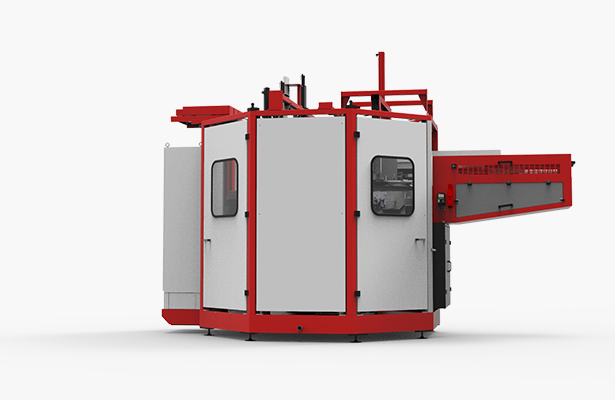

WASCHING CENTRIFUGE

WASHING / DE-OILING

Washing Centrifuge

Now you can manufacture parts JIT (JUST-IN-TIME) from a coil to a clean product with the in-line cleaning process patented by Dr. Goessling. De-oiling, cleaning and drying is accomplished by one piece of equipment and ideally right after the manufacturing machine.

All cleaning processes in the Washing Centrifuge run fully automatic, and the oily parts can be charged in batches. Likewise, the clean parts can be discharged in batches as well. As a result, we are the only Company on the market with a machine that you can use to successfully run a “coil to box” strategy with.

The following steps are performed in a very compact machine design:

|

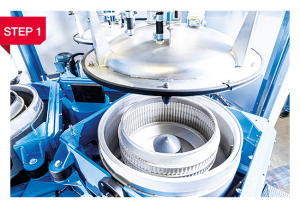

In process station #1 of the Washing Centrifuge, adhesive oils are effectively centrifuged and homogeneously recycled. |

|

|

|

|

Next in process station #2, the bulk material undergoes intensive spray cleaning with highly effective hot washing suds. |

|

|

|

|

Finally in process station #3, the cleaned parts are rinsed with fresh, hot water and dried with hot air. |

|

|

|

|

Afterwards, the drum is emptied. |

| WZ350 | |

|---|---|

| Max. batch weight | approx. 17 lbs. (depends on shape and density of the parts) |

| Max. part length | approx. 4.7” |

| Max. part weight | approx. 2.8 ounces |

| Centrifuging time | min. 60 seconds – max. 300 seconds |

| Total cycle time | min. 80 seconds – max. 320 seconds |

| Max. throughput | approx. 770 lbs. / hour |

| Max. drum rotation speed | approx. 1100 rpm |

| WZ550 | |

|---|---|

| Max. batch weight | approx. 66 lbs. (depends on shape and density of the parts) |

| Max. part length | approx. 6.3 “ |

| Max. part weight | approx. 8.8 ounces |

| Centrifuging time | min. 60 seconds – max. 300 seconds |

| Total cycle time | min. 80 seconds – max. 320 seconds |

| Max. throughput | approx. 2200 lbs. / hour |

| Max. drum rotation speed | approx. 900 rpm |

| Total connection demand | |

| Washing Centrifuge | approx. 14 Amps (please confirm) |

| Tank system | approx. 57 Amps (please confirm) |

WASHING CENTRIFUGE

Applications

"This was achieved to perfection in this plant,

allowing us to uphold our high product standards in the area “product cleaning” as well.”

OLAF AMBROS

Head of Technology & Development at baier & michels

ADVANTAGES

- Low maintenance costs and reduced down times

- Reduced labor expenses, lower logistic costs

- Clean workshop, less transport containers

- Low space requirements

- High throughput

- Part variety

- Recycling of consumables like oils etc.

- Water preparation

- Patented system

- Individual customer solution

The Washing Centrifuge

Read more about the Washing Centrifuge, its options and its advantages.

If you have any questions or are interested, please contact us directly!

Photo Gallery

USAGE

Flexibility in Operation

Cold headed mass parts such as bolts, screws, rivets or round blanks are cleaned automatically by our Washing Centrifuge, as are stamped parts.

Cleaning parts after heat treatment is another application for our machine.

The base components of the cleaning units are three centrifuges that are mounted on a ring mount. Each centrifuge runs through all three cleaning stages,

so there is no transfer of parts in between the centrifuge drums.

The following steps are performed in a very compact machine design:

- centrifuging of the adhesive oils and homogeneous recycling

- spray cleaning of the centrifuged parts with hot suds

- spraying with hot water to wash off excess washing suds

- drying with hot air

ADVANTAGE

Cost Advantages and Use

Thanks to the integration of our unit right after the manufacturing machine, significant cost reductions can be achieved. The cleaning result of this innovative Washing Centrifuge and its reliability are also a noticeable improvement compared to other units available on the market today.

ADVANTAGE

Extremely High Standing Times

The remarkably low carryover of oil into the washing fluids leads to an excellent standing time in the tank system. For example: Thanks to the use of a centralized tank with light liquid separator, the washing fluid only needs to be swapped twice a year when attached to five Washing Centrifuges that run three shifts a day, all year round.

Environmental Certification

You gain an even greater competitive edge because our concept substantially contributes towards meeting the rising requirements

for the ISO 14001 environmental certification.

ADVANTAGE

Drastic Reduction of Oil Usage, Homogeneous Oil Recovery

The high viscosity of the oil on the hot parts enables a very high recovery rate of 95%. The oil is homogeneously recycled. Thus, the costs of buying new oil and paying used oil disposal fees drop dramatically.

ADVANTAGE

Reproducible Cleaning Result

The cleaning capacity of the Washing Centrifuge can be optimally adjusted to the number of manufactured parts. As a result, there is less part overlapping and thus better cleaning results (even with short cycle times). This also reduces the potential for damaged parts. The immediate centrifuging of the hot oil ensures a consistently good and reproducible result, because the short contact time of the oil on the material surface does not allow for any chemical reactions or gumming.

- Low maintenance costs and reduced down times

The centrifuge discharges after the last process step with a tipping motion. This tipping motion ensures a complete and safe emptying of the drum. In contrast to some of our competitor’s systems, a jamming of parts is not possible in our centrifuges. Also, thanks to the solid bowl design of the drum, our centrifuges also cause no problems with leakage.

- Reduced labor expenses, lower logistic costs

In-line cleaning with the Washing Centrifuge reduces the costs of material handling, in-house transport of oily and cleaned parts as well as transport of empty containers. The result is an overall clean bill!

- Clean workshop, less transport containers

In-line cleaning with our Washing Centrifuge reduces the transport time and labor. It also prevents the spreading of oil throughout the workshop from containers and keeps aisleways from being covered in oil or cleaning fluids.

- Low space requirements

Thanks to the compact design of the system, it only requires 10m² of floor space. The Washing Centrifuges can also be integrated into existing production lines, meaning they can be linked to other machines with additional conveying technology.

- High throughput

The Washing Centrifuges are designed with a throughput of 660 – 2200 lbs./ h.

- Part variety

The flexibility of the Washing Centrifuge’s design enables a wide range of part sizes to be processed in a single system. For example: 5/32” x 3/8” up to 5/8” x 6-9/32”.

- Recycling of consumables like oils etc.

By centrifuging the fluids (such as oils used in the production of parts), up to 95% of the fluid can be recycled to the previous process or collected in containers.

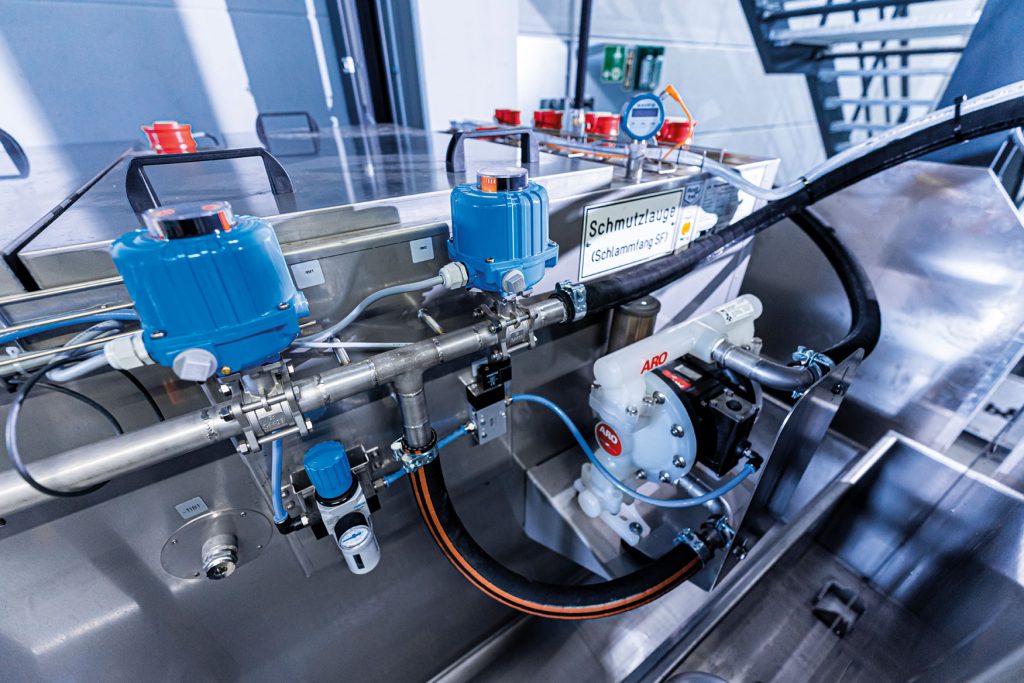

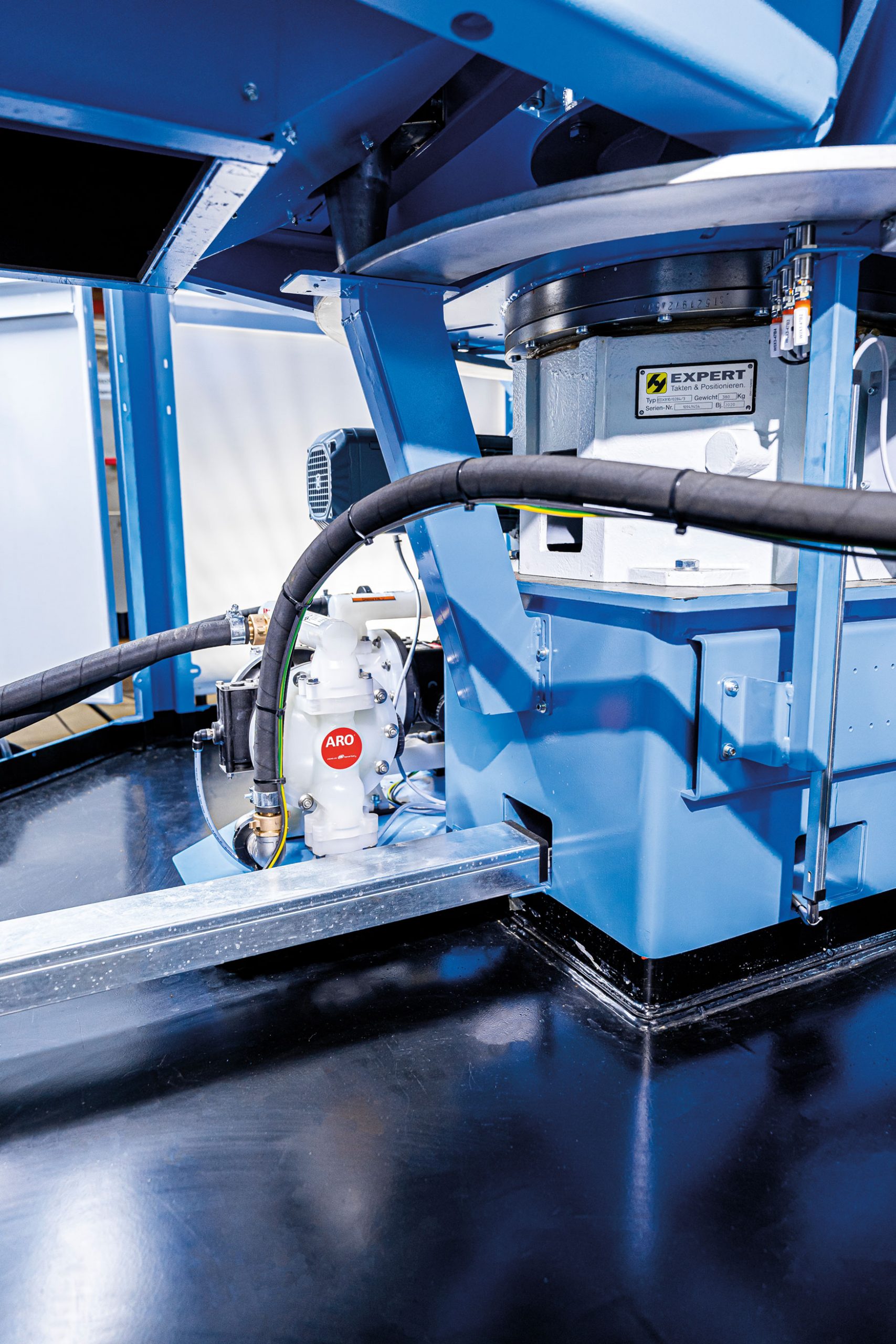

- Water preparation

The Washing Centrifuges operate with washing fluids that are provided by a separate tank system. Our tank systems are usually equipped with an oil separator that removes oil-residue and debris from the process. The water preparation in our tank system enables us to achieve long standing times for the wash and rinsing fluids. The units can naturally also be connected to existing centralized tank systems.

- Patented system

The washing centrifuges are compact and designed as a self-sufficient system. The entire concept is patented and cannot be found anywhere else on the market.

- Individual customer solution

Due to previous implementation of this equipment in mass-production lines for different customers, experience was gained from each customer’s individual needs. We compiled and archived this information for future reference. By utilizing this information and working with the customer, we can fine-tune the equipment to meet his demands, achieving a clean result.

TEST CENTER

Tests With Client Parts

We have a test unit in our test center that can be used to clean various parts. By adjusting to different shapes and demands, we set the foundation to creating a client’s individual, optimal result. To perform tests on site, the test unit will require installation into the production line and sample batches must be ran for results. Feel free to reach out to us for more information!

Washing Centrifuge WZ550

Maximal throughput when de-oiling and cleaning screws or small parts of various dimensions: Dr. Ing. Goessling Maschinenfabrik GmbH,

a subsidiary in the JOEST Group, took on this challenge in a joint effort with baier & michels GmbH & Co. KG, based near Frankfurt.

DO YOU HAVE

QUESTIONS ABOUT

THE WASHING CENTRIFUGE?

CONTACT FORM

Write to us!

You can can contact us quickly and easily using the form below. We will get back to you as soon as possible!

Or you can reach our headquarters at +49 2590 98-0.

LEARN MORE

Other Products