Hinged Belt Conveyors

The robust and flexible

solution for your conveying needs.

The design of our Hinged Belt Conveyors and Hinged Plate Belts aims for high durability and thus optimal productivity of your production plant. We also deliver various accessories for example: Swivel slides and multi-track switches.

Plastic Hinged

Belt Conveyor

For very light-weight and surface-sensitive bulk materials, it can make sense to choose plastic as a belt material. In order to maintain the benefits of the other hinged belt types, we deliver plastic hinged belts in various pitches and widths that utilize the same conveyor structure.

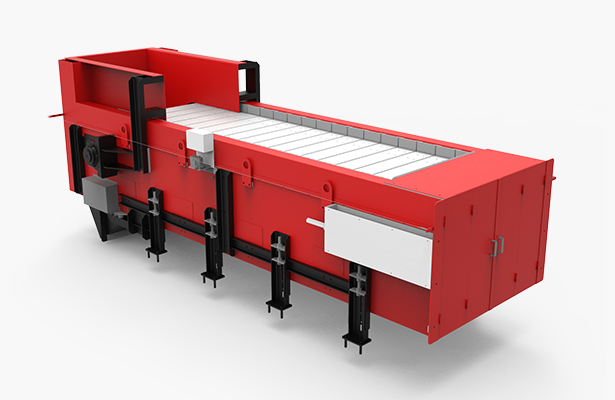

Immersion-Bath Conveyor -

Complete System

or single machine

Discharge conveyors for immersion and quenching baths are important elements in thermal treatment and other conditioning processes. They enable a steady material flow and a reproducible, consistent product quality.

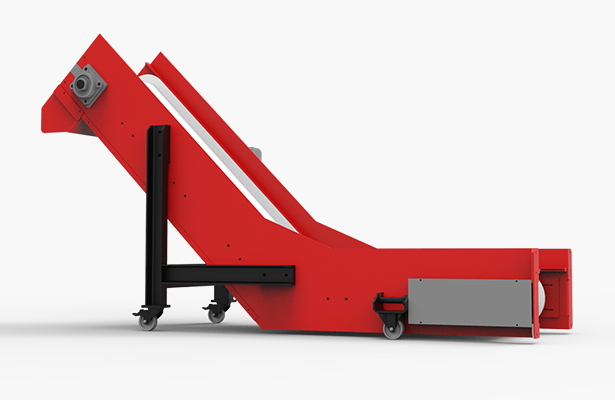

Magnetic Slide Conveyor

Individual layout of the line

H-, L- or Z-Design.

Our Magnetic Slide Conveyors are ideal for use in stamping processes, screw manufacturing, disposal of metal waste and swarf as well as heat treatment of small and sharp “hardened” stock. We deliver Magnetic Slide Conveyors specifically designed for use in stamping presses, punching machines, and chipping machine tools, as well as under floor transport to central scrap disposal stations across long distances.

Hinged Steel Plate Conveyor -

with high adaptability.

We deliver Hinged Steel Plate Conveyors for the transport of heavy materials. This includes glowing hot steel and forging parts, hot and abrasive bulk material such as hot sinter, and used hot forging sand. We also offer Hinged Steel Plate Conveyors that transport scrap metal, waste and other contaminated bulk materials, recycling paper transport (pulper feeding), and as a cooling belt for foundries.

Wire Mesh Belt Conveyor

Transport parts

and bulk material.

The wide spectrum of available wire mesh configurations and materials enable an adaptation to any imaginable application. The high mechanical, chemical and thermal resistance can be particularly useful. That is why our Wire Mesh Belt Conveyors can be found in nearly any industry.

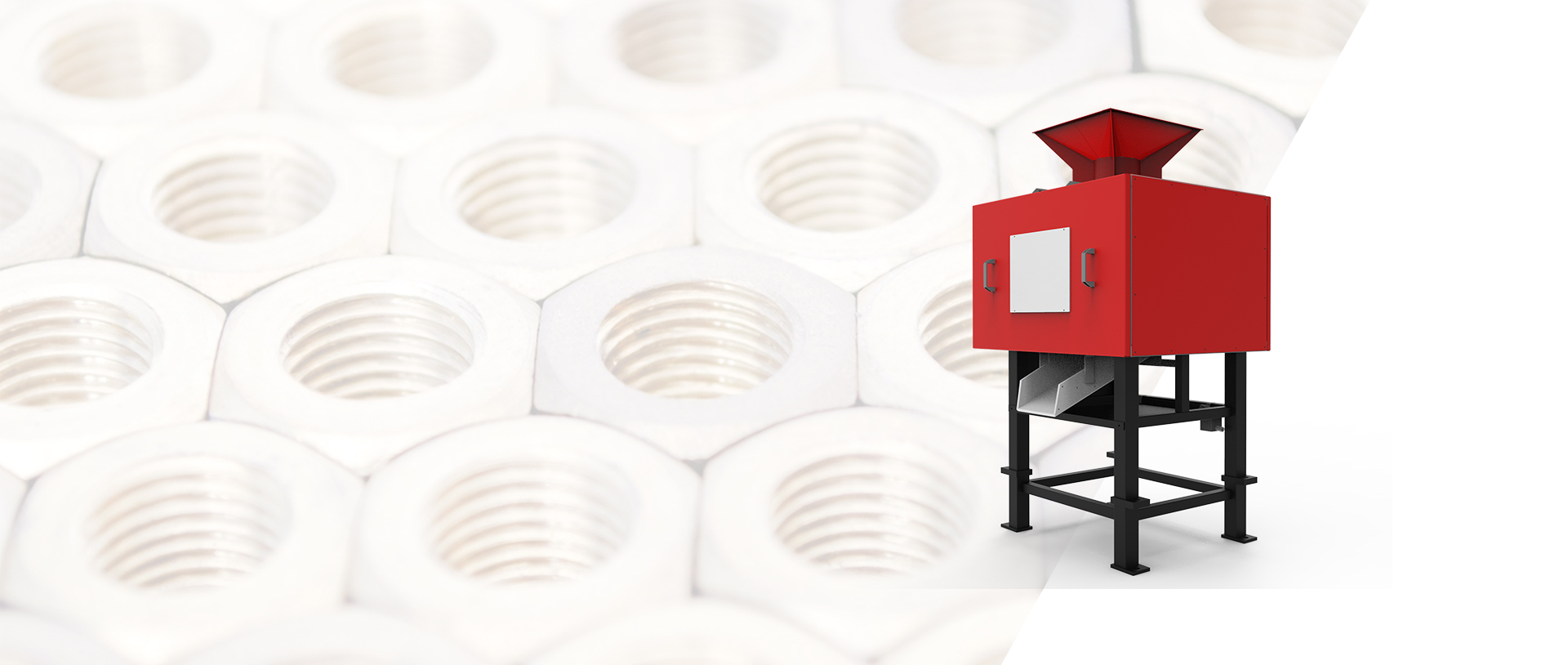

De-Oiling Centrifuge

Immediate recycling

of high-value lubricants.

De-Oiling Centrifuges by Dr. Goessling have been well proven for years in various manufacturing processes world-wide. Especially in the production of screws, nuts or extruded parts, the centrifuges guarantee an effective, continuous manufacturing flow.

Washing Centrifuges

De-oiling, cleaning and

drying - by one piece of equipment.

Now you can manufacture parts JIT (JUST-IN-TIME) from a coil to a clean product with the in-line cleaning process patented by Dr. Goessling. All cleaning processes in the Washing Centrifuge run fully automatic, and the oily parts can be charged in batches.

GOESSLING

Conveying and

Processing Technology

As an internationally operating, middle-class company with 50 years of experience, GOESSLING is one of the leading manufacturers of custom-made conveying and processing technology. Offering individual solutions and complex conveying systems with projects around the world, GOESSLING supplies various sectors of the manufacturing industry ranging from forging, hot and cold forming and stamping, to metallurgy and recycling.

Naturally, all installations and commissioning worldwide are performed on site. The extensive After Sales Service for any modifications, expansions or modernization of plants – including machines from other manufacturers – complete the package.

OUR SOLUTION

For Your Industry

We supply various different components in the area of conveying and processing technology. Large freedom of design regarding technology and our experience from more than 45 years in worldwide projects guarantee individually planned, reliable solutions.

We have experts in sales and construction design from each of our five sales areas who consult you individually and extensively.

QUESTIONS?

OUR PRODUCTS

Individual Solutions

Our product spectrum includes numerous components of conveying and processing technology. Our extensive design and technology options

enable additional individual solution concepts – from basic machines to complex conveying systems.

Convince yourself!

AFTER SALES SERVICE

You Need Spare Parts or Services?

We will be happy to work with you to develop an individual

spare parts and wear concept.

TEST CENTER

Tests with Client Parts

We have a test unit in our test center that can be used to carry out variuos tests. By adjusting to different shapes and demands, we set the foundation to creating a client’s individual, optimal result. To perform tests on site, the test unit will require installation into the production line and sample batches must be ran for results. Feel free to reach out to us for more information!

"The satisfaction of our customers is our motivation.

To ensure this in the long term, we are constantly expanding our range of conveying technology in familiar sectors and also adapting tried-and-tested products to new fields of application and innovative tasks."

DR. MARCUS WIRTZ

Managing Partner JOEST group

CONTACT FORM

Write to us!

You can can contact us quickly and easily using the form below. We will get back to you as soon as possible!

Or you can reach our headquarters at + (423) 915 – 0472.